DL410

Yamato DL410 Large Capacity Spray Dryer

New spray drying technology is fundamentally changing the cannabis industry, with cannabis powder positioned to be the most in-demand product in the next five years. Early adopters of new spray drying technology will benefit most, and the Yamato DL410 spray drying unit is an excellent, large capacity model that will help you set the pace of the rapidly evolving cannabis industry.

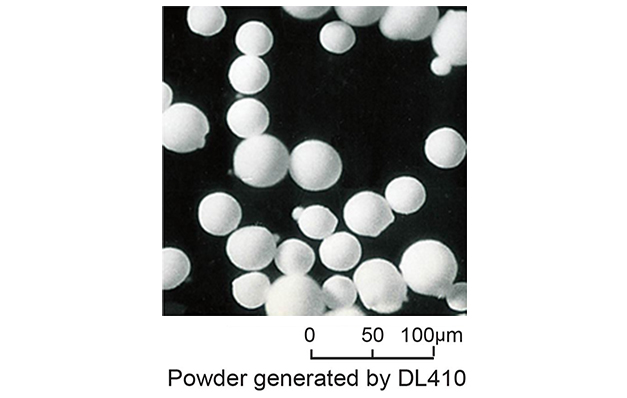

The DL410 produces fine cannabinoid powders ranging from 1 to 100μm. Particles this fine are considered extremely difficult to produce in laboratories, but now you can be the first among the cannabis supply chain to have them on offer.

Interested In Our Yamato DL410 Large Capacity Spray Dryer

Efficiency is an essential part of this model’s design, and is able to directly dry your oil product into fine powder, with no pre- or post-processes (including filtration, separation or pulverization) required. Organic solvents are also supported with the attachment of the GAS410 organic solvent recovery unit. Small, expensive and heat sensitive samples can be dried quickly and efficiently, without any damage to your product.

The DL410 is carefully designed and built to match this evolving industry’s needs, and provides industry best performance and versatility to produce an exceptional, powdered cannabis product.

“The unit is well-built, and Yamato provides good customer support.”

Teeny Tiny Science uses Yamato spray dryers to produce CBD and THC powder in a micro-emulsion process to make edibles more consistent.

“The digital temperature set points are convenient, and the glass collection chamber is beneficial as it allows for visual inspection of the powder quality. Lastly, the unit is also quite easy to clean.”

ADL311SA economical spray dryer purchased in 2021

Expanded with DL410 large capacity spray dryer in 2023

Yamato DL410 Large Capacity Spray Dryer

Benefits

Spray drying allows manufacturers, distributors, retailers and growers to create products that last longer on shelves, cost less to transport and mix better with consumer products than oils. Benefits of using the DL410 to create premium, cannabis powder include:

Lower shipping costs

Spray drying reduces your product’s weight to bioavailability ratio, making it more cost-effective to ship.

Easier storage

Powder is astronomically easier to store than oil.

Longer shelf life

The average shelf life of a spray dried cannabis product is over one year greater than oil.

Absolute solubility

Water and oil don’t mix. Cannabis powder mixes into edibles and drinks better.

A more consistent product

Spray drying makes it easier to produce standardized, cannabinoid-infused products.

Fast-acting, predictable and repeatable experiences

With an onset of 20 minutes, effects that can last up to 4 hours, and consistent product composition from one batch to the next, customers get a more predictable experience.

More eco-friendly choice

From production to shipping, cannabis powder is proven to be a more eco-friendly alternative.

Lab-scale process validation

Produce consistent results for customers, and ensure your product development can keep up with demand with scalable, spray drying technology.

Yamato DL410 Large Capacity Spray Dryer

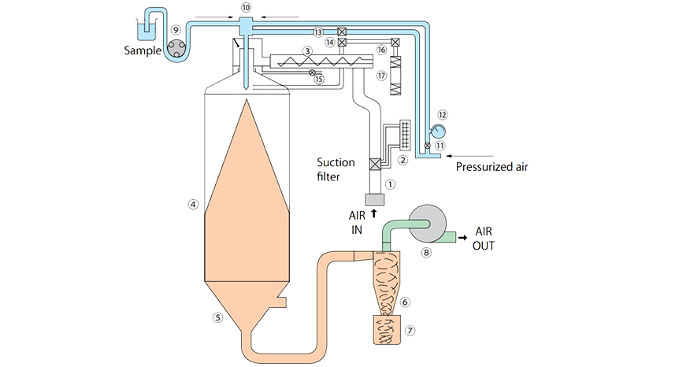

Diagram

No. | Part name

1. Orifice tube

2. Drying air flow meter

3. Heater

4. Drying chamber

5. Drying chamber lower half

6. Cyclone

7. Product vessel

8. Aspirator

9. Sample feed pump

10. Atomizing nozzle

11. Atomizing pressure control valve

12. Atomizing pressure gauge

13. Needle knock Solenoid valve

14. Nozzle blower Solenoid valve

15. Cool air control valve

16. Head elevation control valve

17. Air cylinder for head elevation

Yamato DL410 Large Capacity Spray Dryer

Features

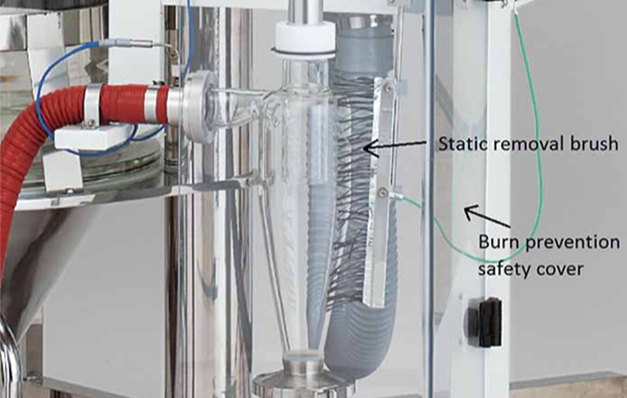

The DL410 spray dryer is built with features that can benefit the cannabis industry at every point in the supply chain: cultivation, production, supplier and retail. With this unit, you can process smaller samples, produce exceptionally fine and pure cannabinoid powder, with no risk of contamination within the spray dryer.

Specific to your needs

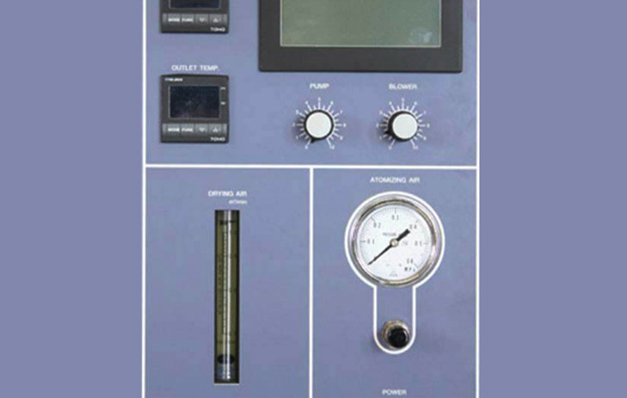

The DL410 spray dryer model comes with a digital display of inlet / outlet temperature and drying air volume. It is also equipped with a detachable drying chamber, cyclone and product vessel, as well as a universal power supply and multilingual touch screen controller.

Quality end product

Small, expensive and heat sensitive samples can be dried quickly and efficiently. Your end product will be fine, pure, contaminant-free powder which is not oxidized and contains minimal moisture.

Efficiency

Directly drying your oil product into fine powder, with no pre- or post-processes (including filtration, separation or pulverization) required. Cleanup is fast and easy.

Maintenance is a breeze

The hot air inlet and drying chamber cover automatically move up and down, and since the cyclone and product vessel can easily be removed, cleaning and maintenance of the spray dryer after production is easy.

User-friendly

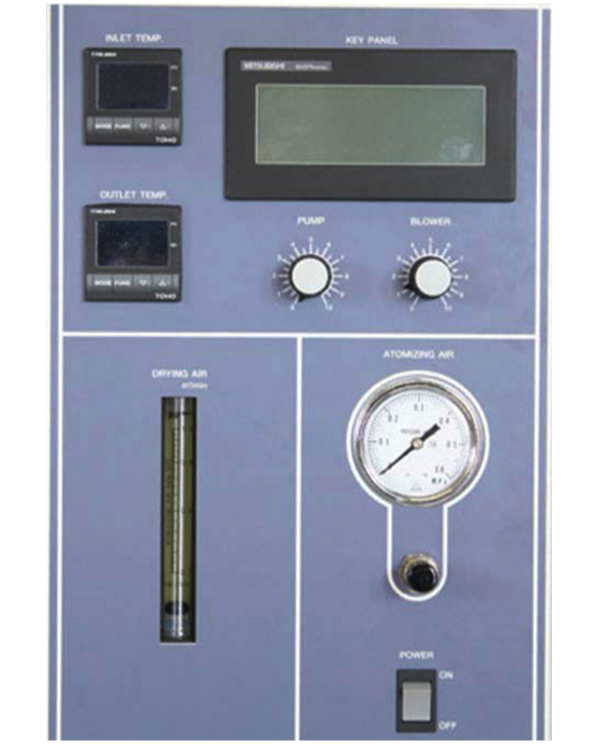

Convenience and efficiency to your business is key. Control functions are conveniently arranged on the control panel, allowing you to customize temperature and drying air volume to your exact needs. From temperature, to air flow, to pressure - you can easily control conditions.

Suitable for heat-sensitive samples

Like the cannabinoids you work with.

Control Panel

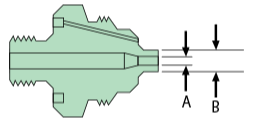

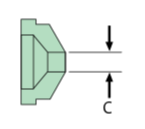

| Model | Nozzle No. | Size (um) |

| 3 (Standard) | (F) 2850 (A) 64 | A 711 B 1270 C 1626 |

| 4 | (F) 60100 (A) 120 | A 1530 B 2550 C 3060 |

| 5 | (F) 100150 (A) 180 | A 2550 B 3825 C 4530 |

Nozzle for liquid (F)

Nozzle for gas (A)

Yamato DL410 Large Capacity Spray Dryer

Technical Specs

| Model | DL410 |

| Water Evaporation Rate | Max. approx. 3000 ml/h |

| Temperature Control Range | 40°C - 300°C at inlet |

| Temperature Control Accuracy | ± 1°C at inlet |

| Dry Air Flow Rate | Max. 1.2 m³/min |

| Air Spray Pressure Control Range | 0 - 600 kPa (0-6 kg/cm²) |

| Spraying System | Two-way nozzle (ø of orifice: 0.7 mm) Nozzle No.3 standard supply |

| Spray/Hot Air Contact System | Downward spray parallel flow system |

| Temperature Controller | PID digital |

| Temperature Sensor | K thermocouple |

| Stainless Pipe Heater | 2kW x 2 at 240V |

| Sample Liquid Feeding Pump | Quantitative peristaltic pump, flow rate variable up to 70ml/min. |

| Solvent Recovery Capability (Option) | Organic Solvent Recovery Unit GAS410 must be used |

| Spray Line Cleaning | Needle inside the nozzle to clean the mesh automatically |

| Safety Devices | Self-diagnostic functions (e.g. temperature aberration); Sample feed reversal |

| Air Spray Pressure Gauge | Bourdon tube: 600k Pa (6 kg/cm²) |

| External Dimensions W X D X H | 1060 x 880 x 1750 mm or 42 x 35 x 69 in |

| Weight | 180 kg or 397 lbs |

| Power Supply | Single Phase AC220V 50/60Hz 24A |

| Included Accessories | Sample liquid tube (Silicone tube - 2 pcs.), safety cover, static removal brush, air hose, exhaust duct |

| Optional Accessories | Organic Solvent Recovery Unit GAS410 |

| Inlet/outlet Temperature Recorder: 212792 - factory installed | |

| Viton/Tiron feeding tube: please inquire | |

| Nozzle: 3 (standard) 4, 5 (optional) | |

| Compressed air: 28 L/min air volume and 8 kgf/cm² compressed air is required | |

| Type of gas: N₂ gas (99.99% purity, medical grade) is required when using GAS410 | |

| Recommended Operational Units | GAS410 Organic Solvent Recovery Unit, GWS410 Organic Solvent Washing Unit |

Downloads

Click on the links below to download the associated PDFs.

Interested In Our Yamato DL410 Large Capacity Spray Dryer?