ADL311SA

Yamato ADL Series Compact & Economical Spray Dryer

New spray drying technology is fundamentally changing the cannabis industry, with cannabis powder positioned to be the most in-demand product in the next five years. Early adopters of new spray drying technology will benefit most, and the Yamato ADL311SA is a great model to start with.

The ADL311SA is the most compact and affordable spray drying option, that efficiently micronizes your liquid cannabis oil into a fine powder. It’s as versatile as your business - both highly mobile on wheels, and can be used as a benchtop unit.

It comes equipped with:

• Unique nozzle cooling mechanism

• Pulse jet mechanism

• Nozzle knocker to help achieve stable, consistent spray drying

Interested in the ADL series compact & economical spray dryer?

Every one of our spray drying systems are carefully designed and built to match your essential needs, and the ADL311SA is no exception! Obtain a combination of high performance, at an economical price with the ADL311SA spray dryer.

Yamato ADL Series Compact & Economical Spray Dryer

Benefits

Spray drying allows manufacturers, distributors, retailers and growers to create products that last longer on shelves, cost less to transport and mix better with consumer products than oils. Benefits of using the ADL311SA to create premium, cannabis powder include:

Lower shipping costs

Spray drying reduces your product’s weight to bioavailability ratio, making it more cost-effective to ship.

Easier storage

Powder is astronomically easier to store than oil.

Longer shelf life

The average shelf life of a spray dried cannabis product is over one year greater than oil.

Absolute solubility

Water and oil don’t mix. Cannabis powder mixes into edibles and drinks better.

A more consistent product

Spray drying makes it easier to produce standardized, cannabinoid-infused products.

Fast-acting, predictable and repeatable experiences

With an onset of 20 minutes, effects that can last up to 4 hours, and consistent product composition from one batch to the next, customers get a more predictable experience.

More eco-friendly choice

From production to shipping, cannabis powder is proven to be a more eco-friendly alternative.

Lab-scale process validation

Produce consistent results for customers, and ensure your product development can keep up with demand with scalable, spray drying technology.

Yamato ADL Series Compact & Economical Spray Dryer

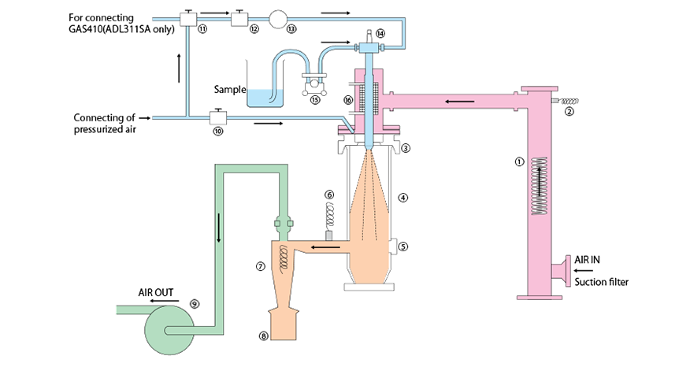

Diagram

No. | Part name

1. Heater

2. Inlet temperature sensor

3. Distributor

4. Drying chamber

5. Cap

6. Outlet temperature sensor

7. Cyclone

8. Product collecting container

9. Blower

10. Solenoid valve

11. 3-way solenoid valve (ADL311SA only)

12. Needle valve

13. Pressure meter

14. Spray nozzle

15. Liquid sending pump

16. Nozzle cooling mechanism connecting port

Yamato ADL Series Compact & Economical Spray Dryer

Features

The ADL311SA spray dryer is built with features that can benefit the cannabis industry at every point in the supply chain: cultivation, production, supplier and retail. This model is:

User-friendly

This model is easy to set up and operate, with a one-touch detachable mechanism for the drying chamber and cyclone

Suitable for heat-sensitive samples

As high heat is not directly applied to fine dry powder

Quality end product

Your end product will be fine, pure, contaminant-free powder which is not oxidized and contains minimal posture

Efficient

Directly drying your oil product into fine powder, with no pre- or post-processes (including filtration, separation or pulverization) required.

Safe

Explosion-free working is guaranteed in combination with GAS410 due to oxygen & pressure control within the spray dryer

Eco-friendly

Organic solvents are recovered in a closed loop to protect the environment by minimizing pollution

Versatile

The ADL311SA spray dryer is highly mobile on wheels, or usable with shorter height as a benchtop unit by removing the moveable caster

Economical

Our most affordable unit, without sacrificing product quality.

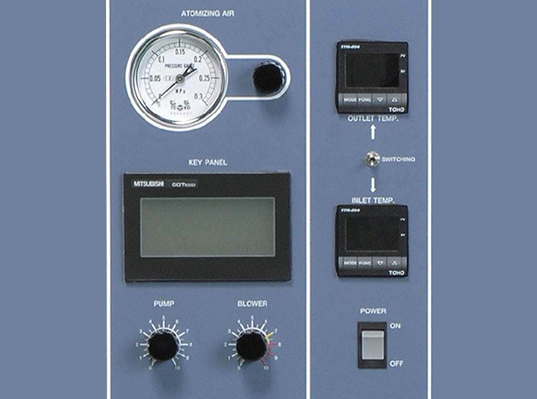

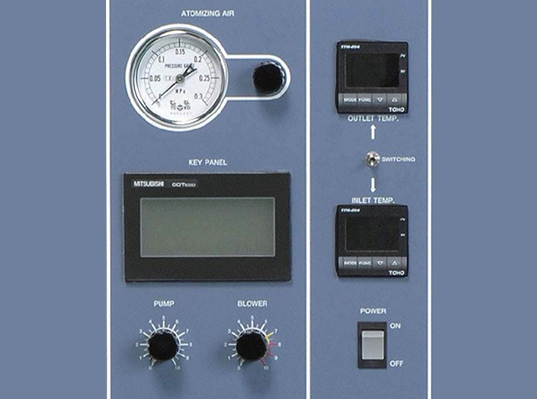

Control Panel

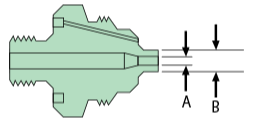

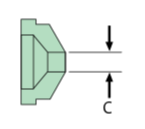

| Model | Noozle No. | Size (um) |

| 1A Standard | (F) 1650 (A) 64 | A 406 B 1270 C 1626 |

| 1 | (F) 2050 (A) 64 | A 508 B 1270 C 1626 |

| 2A | (F) 2050 (A) 70 | A 508 B 1270 C 1778 |

| 2 | (F) 2850 (A) 70 | A 711 B 1270 C 1778 |

| 3 | (F) 2850 (A) 64 | A 711 B 1270 C 1626 |

Nozzle for liquid (F)

Nozzle for gas (A)

Two-way Nozzle System

Tip of the Nozzle comprises of a nozzle for liquid and a nozzle for gas.

Easy to take apart for cleaning to prevent contamination

Yamato ADL Series Compact & Economical Spray Dryer

Technical Specs

| Model | ADL311SA |

| Supported Samples | Water soluble samples |

| Evaporated Water Amount | Max. 1300 mL/h |

| Spraying System | Two-way nozzle, Nozzle No. 1A as standard (0.4mm) |

| Temp. Adjusting Unit Setting Range | 40 to 220°C (inlet temperature), 0 to 98°C (outlet temperature) |

| Temperature Adjusting Accuracy | Inlet temperature ±1°C |

| Drying Air Amount Adjusting Range | 0 to 0.7 m³/min |

| Spray Air Pressure Adjusting Range | 0 to 0.3 MPa |

| Liquid Sending Pump Flow Rate Range | 0 to 26 mL/min |

| Spray Air Line Washing Function | Spraying at the nozzle tip, manual pulse jet system |

| External Output | Inlet temperature, outlet temperature, temperature outlet (4-20 mA) |

| Temperature Adjusting Device | PID digital |

| Touch Panel | Blower, heater, liquid sending pump, pulse jet switch, error display |

| Control Select Switch | Inlet temperature, outlet temperature control switch (outlet temp. control is conditional) |

| Temperature Sensor | K thermocouple |

| Heater | 2.0kW (at 200V) to 2.88kW (at 240V) |

| Liquid Sending Pump | Fixed amount peristaltic pump |

| Spraying Air Pump | For water soluble samples air compressor is used (sold separately). For organic solvent samples the integrated compressor in GAS410 is used (no separate air compressor required). |

| Service Outlet | For stirrer: AC115V, max. 2A |

| Suction Blower | Bypass blower |

| Filter | Suction filter, exhaust filter |

| Recovery Of Solvent | Use Organic Solvent Recovery Unit GAS410 (sold separately) |

| Spray Nozzle Cooling Mechanism | Connector: nipple x 2, O.D.:ø10.5 mm |

| Spray Air Connection Diameter | Nipple diameter: ø7 mm |

| Spray Air Pressure | Bourdon tube: 0.3 MPa |

| Exhaust Connecting Diameter | ø50mm |

| Safety Function | Inlet/outlet temperature overheat, sample feed reverse rotation mechanism, over current electric leakage breaker, nozzle connection error |

| External Dimension WxDxH | 580 x 420 x 1125 mm |

| Weight | 80 kg |

| Power Supply | Single Phase AC200V~240V 50/60Hz 16~18A Switching of terminals necessary |

| Included Accessories | Silicon tubes (with a stopper) x 3, exhaust duct (with one hose band) x 1, outlet temperature sensor, spray air tube, sample box, static electricity removal earth, "Tetron" braided tube hose 5m (with two hose bands) |

| Recommended Operational Units | GAS410 Organic Solvent Recovery Unit, GWS410 Organic Solvent Washing Unit |

Downloads

Click on the links below to download the associated PDFs.

Yamato ADL Series Compact & Economical Spray Dryer

Video Tutorial